High Efficiency Compost Cover Placement Organic Fertilizer

Production Equipment

Product Description:

High Efficiency Compost Cover Placement Organic Fertilizer Production Equipment

High Efficiency Compost Cover Placement Organic Fertilizer Production Equipment

In order to recycle organic waste, compost cover systems have

proven to be an effective method. This process involves depositing

organic waste in designated areas and using mulch to insulate and

regulate the decomposition process.

The functionality of the organic fertilizer composting fermentation

facility equipment is based on the practice of placing organic

waste in a suitable compost pile and covering it with mulch (such

as plastic film, straw, lawn clippings, etc.). This helps to

control the temperature, humidity, and oxygen levels, creating an

ideal environment for microbial decomposition.

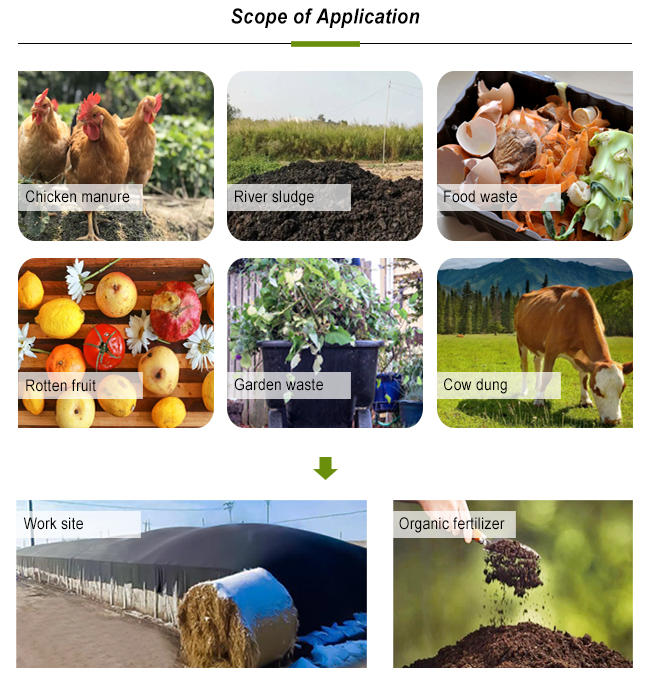

The compost cover placement machine is versatile and can be used in

various settings, including farms, breeding farms, garbage

treatment plants, and landscape gardens. In addition, it is capable

of producing high-quality organic fertilizer in colder environments

and has the capability to quickly store and dispense covering

materials. By utilizing organic waste for composting, resources can

be effectively recycled, reducing environmental pollution and

improving soil quality.

Features:

Compost Cover Placement Organic Fertilizer Production Equipment: Enhance Your Composting Experience

The Organic Fertilizer Production Equipment is a highly recommended

choice, offering a range of benefits for your composting needs. Its

exceptional features make it stand out from traditional compost

covering methods. With this machine, you can expect improved

efficiency, quality, and convenience in your composting process.

Advanced Sealing Function

One of the main advantages of this machine is its superior sealing

function. Compared to manual covering, it provides a much stronger

and more secure seal. This ensures complete coverage of the

compost, eliminating any gaps that may lead to moisture

evaporation.

Enhanced Efficiency

The machine offers efficient control over humidity, temperature,

and oxygen supply in your compost. This leads to quicker

transformation of organic matter, resulting in improved

fermentation efficiency and final product quality.

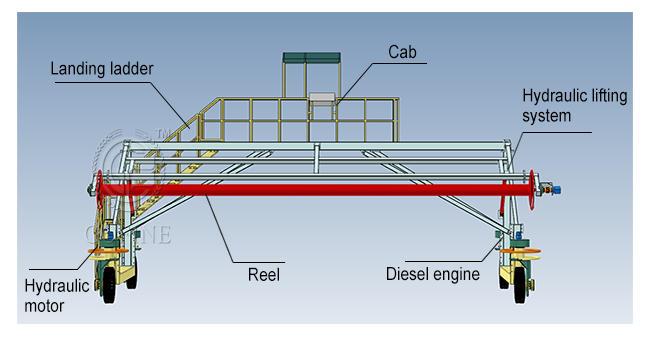

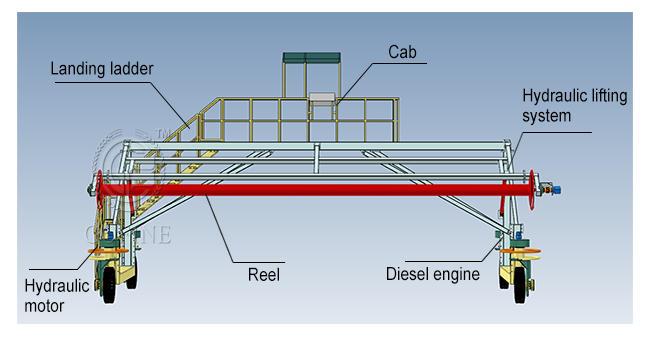

Convenient Remote Control

The remote control system makes movement of the machine easy and

accurate. With a digital panel for precise and intuitive control,

the machine also comes equipped with emergency stop buttons and

other protective features.

Durable Material

The machine is constructed with high-quality carbon steel, known

for its strength and corrosion resistance. This ensures

long-lasting performance and reliability.

Multi-functional

The versatility of the machine allows it to be used with a variety

of materials, including nanofilm coverings and lawn clippings. This

makes it suitable for various types of composting situations.

Technical Parameters:

| Technical Parameters | Product Description |

|---|

| Raw Material | Organic Waste |

| Product Name | Compost Cover Placement Organic Fertilizer Production Equipment |

| Service | OEM/ODM |

| Fertilizer Efficiency | High |

| Product Form | Powder/Granular |

| Shelf Life | 2 Years |

| Moisture Content | ≤60% |

| Nutrient Content | High |

| Production Capacity | Customized |

| Usage | Organic Fertilizer Making Machine |

| Key Words | composting making machine, organic fertilizer machine, organic

fertilizer machine factory |

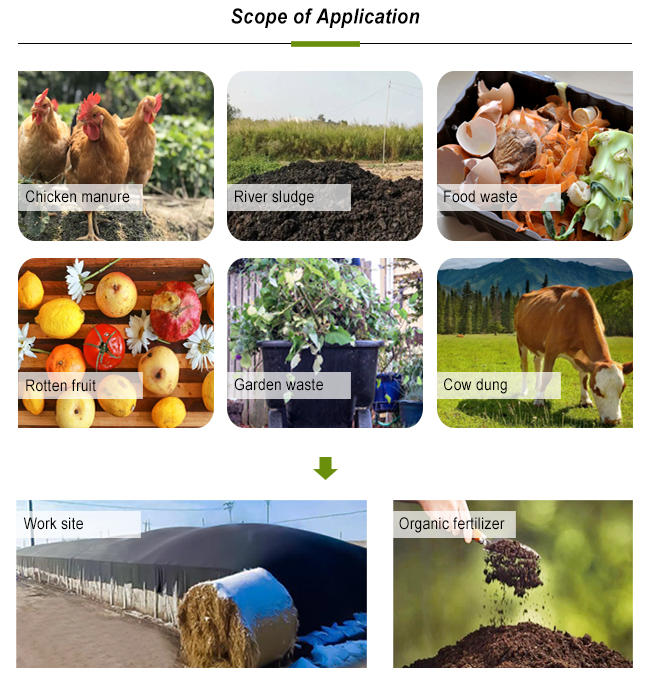

Applications:

Compost Cover Placement Organic Fertilizer Production Equipment Working Process:

The use of a canopy-laying compost recycling cover machine has

greatly increased the efficiency of organic fertilizer production.

This process involves four main steps:

- Setting up the compost site

- Covering the compost

- Crushing and mixing

- Processing and packaging the fertilizer

To begin, a compost site is carefully selected and prepared for

use. The site should be located in a suitable area and contain a

variety of raw materials, such as organic fertilizers, poultry

manure, and food waste. These materials are then stacked together

inside the compost site.

Next, the compost covering equipment is used to cover the compost

with a protective layer of plastic film. This is done using an

intelligent remote control system, which allows for precise and

efficient coverage. By creating a closed environment, the compost

is shielded from excess heat and moisture, thus promoting the

natural restructuring and fermentation of the organic materials.

Once the compost is properly covered, it is then processed through

a crushing and mixing device. This device crushes the materials

into the desired fineness and mixes them together thoroughly.

The final step is to process and package the fertilizer for use.

This can be done through packaging equipment or through the use of

granulation equipment, which turns the fertilizer into compact

granules. The finished product is then packaged and ready for use

as a natural and beneficial fertilizer for plants and crops. With

the help of the canopy-laying compost recycling cover machine, the

entire process is streamlined and highly efficient.

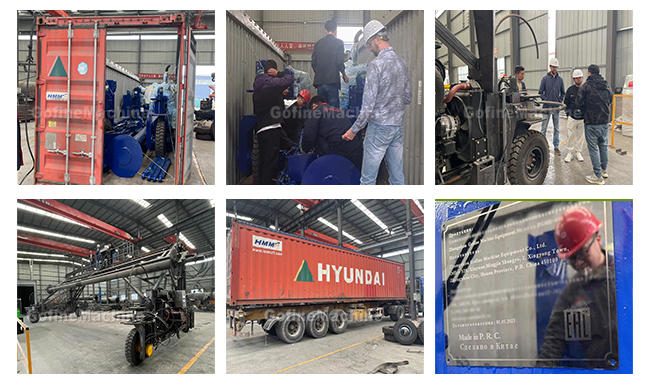

Customization:

Compost Cover Placement Organic Fertilizer Production Equipment Customized Service - Gofine

Brand Name: Gofine

Model Number: L-10

Place of Origin: China

Certification: CE

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: plywood case

Delivery Time: 1-3 Sets/15days

Payment Terms: Western Union, L/C, T/T, MoneyGram

Supply Ability: 25 Sets/Month

Nutrient Content: High

Fertilizer Efficiency: High

Production Capacity: Customized

Moisture Content: ≤60%

Application Area: Agriculture

With our customized Compost Fertilizer Production services, you can

trust Gofine to provide the best quality and efficiency for your

fertilizer needs.

Our organic fertilizer machines are designed to produce

high-quality fertilizer compost for your agricultural needs.

Our compost turning machines and equipment are engineered for

optimal performance and durability.

Choose Gofine for your fertilizer compost needs and experience high

nutrient content and efficiency in your production.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Gofine. - Q: What is the model number of this product?

A: The model number of this product is L-10. - Q: Where is this product manufactured?

A: This product is manufactured in China. - Q: Does this product have any certification?

A: Yes, this product is CE certified. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1. - Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable. - Q: How is this product packaged?

A: This product is packaged in plywood cases. - Q: What is the delivery time for this product?

A: The delivery time for this product is 1 to 3 sets within 15

days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are Western Union,

L/C, T/T, and MoneyGram. - Q: What is the supply ability for this product?

A: The supply ability for this product is 25 sets per month.