Disc Pan Pelletizer Fertilizer Granules Fertilizer Production

Manufacturer Plant for NPK 15-15-15

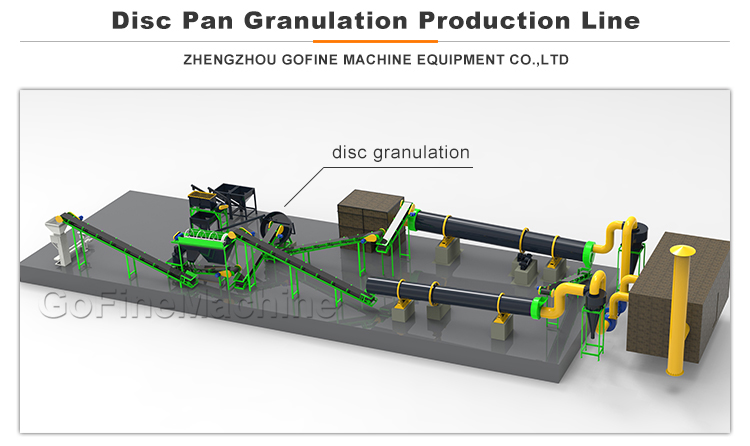

● Introduction of Disc Granulator Fertilizer Production Line

The disc granulation production line is designed for the production

of both organic and compound fertilizer granules. It is also

suitable for recycling and granulation of organic waste. This

production line is widely used in various industries such as plant

planting, bentonite cat litter, and laundry fragrance beads. The

disc granulator has a high ball forming rate of up to 93%, making

it a highly efficient choice for fertilizer production. Equipped

with an unpowered scraper and smooth running motor, it guarantees a

long service life.

Our complete granulation production line includes a feeding system,

disc granulator, and packaging machine. We provide a turnkey

solution for all your granulation needs, accompanied by meticulous

after-sales installation services to ensure your satisfaction.

Features:

Disc Granulation Production Line

The disc granulation production line is a commonly used production

equipment in the fields of granular fertilizers, chemical

fertilizers, and others. Its advantages can be summarized as

follows:

1. Efficient Production

The disc granulation production line boasts high production

efficiency. The resulting granular products are regular and round,

with a balling rate of up to 95%, greatly improving production

efficiency.

2. Wide Scope of Application

The disc granulation production line is suitable for granulating

various powdery and wet raw materials, including the production of

chemical fertilizers, granular fertilizers, compound fertilizers,

bentonite, snow melting agents, and more.

3. Easy Operation

Operating the disc granulation production line is relatively simple

due to its uncomplicated equipment structure. Additionally, it is

easy to control and maintain, with trained staff able to operate it

with skill.

4. Good Granule Quality

The granules produced by the disc granulation production line have

regular shapes, smooth surfaces, uniform sizes, and good quality,

making them suitable for long-distance transportation and storage.

5. Environmental Protection and Energy Saving

The disc granulation production line does not require the use of

additives during the production process, avoiding environmental

pollution. It also effectively utilizes raw materials and reduces

energy consumption.

6. Flexible and Diverse

The disc granulation production line can be adjusted and improved

to meet different raw materials and product requirements, making it

suitable for a variety of production needs.

Technical Parameters:

| Product Name | Compound Fertilizer Production Line |

|---|

| Advantage | Full Auto, Simple Operation, Save Labor |

|---|

| Material | CS/SS |

|---|

| Raw Material | Chemical Granules Or Powder |

|---|

| Control System | PLC Control System |

|---|

| Application | Granules Production |

|---|

| Granules Shapes | Ball Shape |

|---|

| Capacity | 3-5T/H |

|---|

| Pellet Size | 3-8mm |

|---|

| Customization | Available According To Customer's Specific Requirements |

|---|

| Working Method | Wet Granulation |

|---|

| Product Name | Fertilizer Granulator Plant |

|---|

| Advantage | Full Auto, Simple Operation, Save Labor |

|---|

| Material | CS/SS |

|---|

| Raw Material | Chemical Granules Or Powder |

|---|

| Control System | PLC Control System |

|---|

| Application | Granules Production |

|---|

| Granules Shapes | Ball Shape |

|---|

| Capacity | 3-5T/H |

|---|

| Pellet Size | 3-8mm |

|---|

| Customization | Available According To Customer's Specific Requirements |

|---|

| Working Method | Wet Granulation |

|---|

| Product Name | Bio Fertilizer Production Line |

|---|

| Advantage | Full Auto, Simple Operation, Save Labor |

|---|

| Material | CS/SS |

|---|

| Raw Material | Chemical Granules Or Powder |

|---|

| Control System | PLC Control System |

|---|

| Application | Granules Production |

|---|

| Granules Shapes | Ball Shape |

|---|

| Capacity | 3-5T/H |

|---|

| Pellet Size | 3-8mm |

|---|

| Customization | Available According To Customer's Specific Requirements |

|---|

| Working Method | Wet Granulation |

|---|

| Product Name | Fertilizer Making Machine |

|---|

| Advantage | Full Auto, Simple Operation, Save Labor |

|---|

| Material | CS/SS |

|---|

| Raw Material | Chemical Granules Or Powder |

|---|

| Control System | PLC Control System |

|---|

| Application | Granules Production |

|---|

| Granules Shapes | Ball Shape |

|---|

| Capacity | 3-5T/H |

|---|

| Pellet Size | 3-8mm |

|---|

| Customization | Available According To Customer's Specific Requirements |

|---|

| Working Method | Wet Granulation |

|---|

Applications:

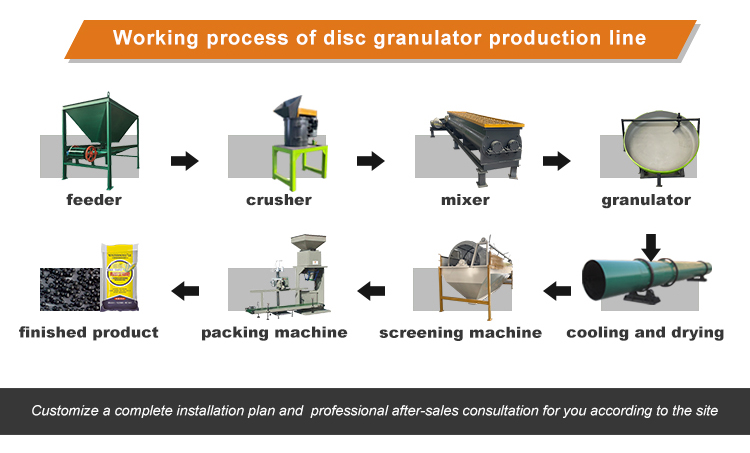

The Production Process of the Disc Type Compound Ferrtilizer

Production Line:

The production process of the disc production line can be divided

into six main steps:

1. Ingredients Mixing

In this step, organic substances, inorganic substances, and

auxiliary substances are mixed in precise proportions using

batching equipment. This ensures the accuracy of the raw material

proportions.

2. Crushing and Mixing

The lumpy raw materials are crushed and mixed together to make them

easier to granulate and maintain uniformity.

3. Disc Granulation

The mixed raw materials are then rolled in a disc granulator to

form uniform, high-density spherical granules.

4. Drying and Cooling

The newly made granules are sent to a drying equipment to remove

moisture, increase hardness, and undergo cooling processing to

ensure stability and quality.

5. Grading and Screening

The granules are graded using screening equipment to ensure they

meet the required size. Any unqualified particles can be returned

to the granulation process.

6. Packaging and Storage

The final step involves using automated packaging equipment to

weigh and package the granules. They are then either stored or sold

directly to ensure product quality and meet market demand.

This is the basic process of the disc fertilizer granulation

production line. Each step requires careful planning and strict

control to ensure the production of high-quality fertilizer

granules.

Customization:

Customized Service for Compound Fertilizer Production Line

Brand Name: Gofine

Model Number: 20-40 m2

Place of Origin: China

Certification: CE

Minimum Order Quantity: 1

Price: Negotiation

Packaging Details: plywood case

Delivery Time: 1-3Sets/15days

Payment Terms: L/C, Western Union, T/T, MoneyGram

Supply Ability: 15Sets/Month

Machine Type: Disc Fertilizer Granulator Machine

Application Materials: Powder

Packaging Method: Automatic Packaging Machine, Manual Packaging

Machine

Granules Shapes: Ball Shape

Raw material: Chemical Granules Or Powder

At Gofine, we specialize in providing customized services for

compound fertilizer production line. Our line includes high-quality

fertilizer equipment such as disc fertilizer granulator machine,

which is suitable for powder materials. We offer various packaging

methods including automatic and manual packaging machines, and our

granules are shaped in perfect ball shape. Our raw materials are

chemical granules or powder, ensuring the best quality for your

fertilizer. With our expertise and experience in this field, we

guarantee the best results for your fertilizer manufacturing needs.

Packing and Shipping:

Packaging and Shipping

The Compound Fertilizer Production Line will be packaged in a

sturdy wooden case to ensure safe transportation. The case will be

securely sealed and labeled with the product name, specifications,

and production date. Inside the case, the main equipment will be

wrapped with protective materials to prevent any damage during

shipping.

The packaging will also include a user manual and necessary tools

for installation and operation.

The shipping process will be arranged by our team and we will

choose the most suitable shipping method based on the customer's

location and requirements. We will ensure timely delivery and

provide tracking information to the customer.

Upon arrival, the customer should carefully inspect the package for

any damages. In case of any issues, please contact us immediately

and we will provide a solution.