Product Description:

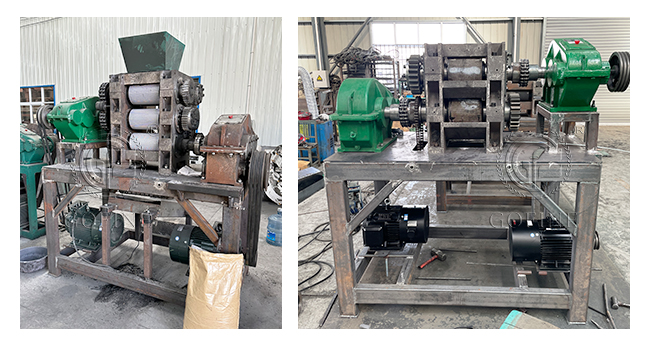

The Dry Granulator Fertilizer Compactor Machine is a highly efficient piece of equipment for dry granulation,

featuring advanced technology and a compact design. Its practical

and novel design ensures low energy consumption, and it can also

form a small production line with other supporting equipment. This

granulator boasts the ability to achieve continuous production at

room temperature, making it a versatile option for granule

production in fields such as compound fertilizers, organic

fertilizers, inorganic fertilizers, cat litter, graphite,

snow-melting agents, detergents, and more.

Perhaps even more impressively, this granulator can produce

high-quality products without the need for drying, which sets it

apart from other granulators on the market. Additionally, its

versatility allows it to produce high, medium, and low

concentrations of special compound fertilizers that are ideal for a

variety of different crops.

Overall, the double roller granulator is an exceptional piece of

equipment that offers a number of unique benefits in the world of

granule production. With its practical design, low energy

consumption, and ability to produce high-quality products without

the need for drying, it is a top choice for professionals in the

field.

Features:

Dry Granulator Fertilizer Compactor Machine it is possible to

complete the granulation process successfully without the need to

incorporate any binder. This is a significant advantage, as it

eliminates the need to add any potentially harmful chemicals into

the product.

Another significant benefit of the granulation process is that it

can be achieved at room temperature. This eliminates the need for a

time-consuming and potentially costly drying process, which can

save time and resources for the manufacturer.

The size and hardness of the granules can be easily manipulated by

adjusting the pressure and size of the double rollers. This

customization feature of the process allows manufacturers to tailor

their product to meet specific requirements, making it an ideal

solution for a wide range of applications.

The granulation process has a small footprint, making it suitable

for smaller manufacturing facilities. Additionally, it has low

energy consumption, which can help reduce operational costs.

Lastly, the process has excellent anti-corrosion properties,

ensuring that the equipment can be used for a long lifespan,

providing economic benefits in the long term.

Technical Parameters:

| Product Name: | Dry Granulator Fertilizer Compactor Machine |

| Model: | Double Roller Press Extrusion Granulator Machine |

| Product Type: | Fertilizer Granulator Machine |

| Final Granule Size: | Diameter 2-20mm |

| Roller: | 300x150mm, Alloy Steel |

| Installation: | Guide |

| Roller Diameter: | 200mm |

| Material: | Carbon Steel Or Stainless Steel (customizable) |

| Roller Size: | 300x150mm |

| Capacity: | 1-2t/h |

| Use: | Powder Material Processing |

| Granulation Rate: | >98% |

| Features: | Dry Granulator |

Applications:

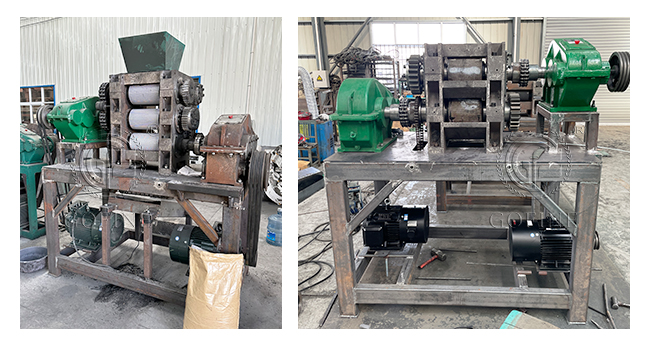

The dry extrusion granulation method is utilized by the Dry

Granulator Fertilizer Compactor Machine, which offers an efficient

way of converting materials into granules. In this process, a belt

and pulley mechanism is driven by an electric motor to initiate the

granulation process. The machine's driving shaft passes through the

reducer and works in coordination with the gear and opposite driven

shaft.

As the granulation process starts, the materials are fed into the

machine through the hopper. Afterward, they are pressed by a set of

rollers resulting in the formation of compact ball cakes. The

roller extrusion ensures that the size of the granules is

consistent and uniform.

The granules that are formed in the previous step are separated by

a crushing screen. The screen breaks the compact ball cakes

resulting in uniformly shaped oval particles. Using the double

roller granulator ensures consistent particle size of the granules

produced.

Support and Services:

The Dry Granulator Fertilizer Compactor Machine is a machine

designed for producing organic fertilizer and compound fertilizer

granules. It uses squeezing principle to form fertilizer materials

with diameters of 3.5-10mm in one time. This fertilizer granulator

machine is widely used in the organic fertilizer production line,

compound fertilizer production line, and BB fertilizer production

line.

The product technical support and services for the Double Roller

Fertilizer Granulator include:

- Technical guidance for installation, commissioning, and operation

- Regular maintenance and repair services

- Replacement of parts and components

- Online technical support

- Training services for operators and maintenance personnel

Our team of experienced technicians and engineers is dedicated to

providing high-quality technical support and services to our

customers. We are committed to ensuring the long-term and reliable

operation of our products.

Packing and Shipping:

Product Packaging:

- 1 set per wooden case

- Dimensions: 1350mm x 750mm x 1150mm

- Gross weight: 500kg

Shipping:

- Shipping method: By sea, by air or by land

- Delivery time: Within 15-30 days after receiving the deposit

- Port of shipment: Qingdao Port, China

FAQ:

Q: What is the brand name of this Dry Granulator Fertilizer Compactor Machine?

A: The brand name of this fertilizer granulator is Gofine.

Q: What is the model number of this fertilizer granulator machine?

A: The model number of this fertilizer granulator is DZJ-I-2.0.

Q: Where is this fertilizer granulator made?

A: This fertilizer granulator is made in China.

Q: Does this fertilizer granulator have any certification?

A: Yes, this fertilizer granulator has CE certification.

Q: What is the minimum order quantity for this fertilizer

granulator?

A: The minimum order quantity for this fertilizer granulator is 1.

Q: What is the price of this fertilizer granulator?

A: The price of this fertilizer granulator is negotiable.

Q: How is this fertilizer granulator packaged?

A: This fertilizer granulator is film packed in a Container.

Q: What is the delivery time for this fertilizer granulator?

A: The delivery time for 1-3 sets is 15 days.

Q: What are the payment terms for this fertilizer granulator?

A: The payment terms for this fertilizer granulator are Western

Union, MoneyGram, L/C, and T/T.

Q: What is the supply ability of this fertilizer granulator?

A: The supply ability of this fertilizer granulator is 25 sets per

month.